Norrtälje, Sweden

Enabling Scalable and Mobile Automation for Future-Proof Assembly Lines

One of our customers came to us with a fully developed product with the mission to make the assembly of their product automated. But investing in a robot assembly line is a big commitment, so making sure the robot line could easily be changed and adapted to similar and future products was essential. The automated assembly line should also be able to be moved to a different location if needed.

We have worked closely together with the customer and their material suppliers for the last year to both develop an automated pilot assembly line, but also to make the products materials adapted for automated production. Things that are easy for human hands can be challenging to automate as in this case, pealing of protective films.

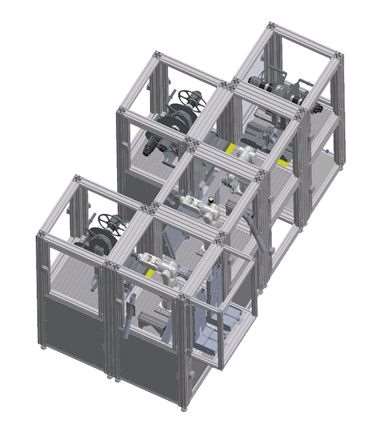

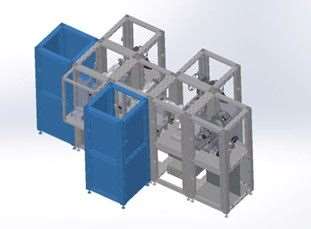

Cicor Nordic Engineering solved the customer's needs by developing a module-based assembly line that is easy to expand, change, upgrade and move. The inside of the cell fulfils ISO8 cleanroom standards with filtered overpressure ventilation from the top.

Each individual module is small enough to be shipped on an EU-pallet. All sides of one module can be equipped with doors, closed panels or an additional module block. The lower part of the modules accommodates all electrical and pneumatical control equipment. All surfaces on the cell have T-slot system for mounting of more hardware.

A module can for example hold a small ABB IRB1100 robot, material feeders, or equipment for the robot to interact with. For this assembly line we equip the cells with smart cameras, fixtures and material feeders to assist three IRB 1100 robots. The robot line assembles 10 different materials and aligns them together within 0,1mm.

Niclas Rasmusson

Mechanical